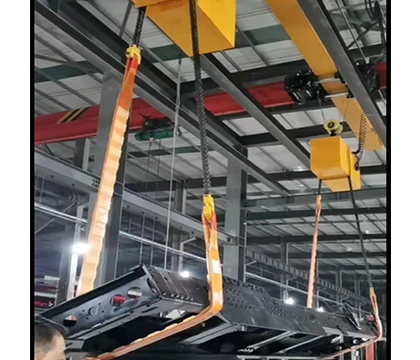

Load turner system can be attached to a conventional crane and, with the help of tear-resistant slings or chains, also enables difficult-to-balance objects to be safely controlled in every position. Depending on the size and weight of the building element, the system runs on a rotating beam and can be connected to a drive with appropriate freewheeling. Even very heavy mould components can be turned over in a few minutes.

Moulding box also named moulding flask, mold flask, sand flask, sand box, which is the key equipment during the casting production. Chains Load Turner Systems are recommended for capacities over 20 tons and for hot goods. They are also more suitable than polyester belts in harsh environments.

Featuring two endless chains, which are secured around the trunnions of the moulding boxes using driving dogs, the KFCS load turning device lifts the moulding boxes and feeds the chains through parallel drive wheels at the same speed to effect a controlled reorientation of the load.

How To Use The Load Turner System

1. Check the position of the pulley and make sure that the lock is in place.

2. Lift the load just above the ground to check it's balance: Balance the load by adjusting the strops according to the lifted load length and the position of the center of gravity.

3. It's imperative that the load is balanced from both sides before it is lifted.

4. Lift the load high enough to a suitable height for the load to be turned.

5. The load must have a minimal weight of 20% of the device WLL.

Test trials should be conducted for loads below 20%.

6. Once the load is lifted to a sufficient height, use the remote to turn the load into the desired position.

7. After the load is turned to the desired position, then bring it down to the ground level.

Options of Load Turner System

• Alarm for imbalanced lifting: In such cases, you should bring the load down and balance it again by adjusting the straps.

• Synchronization rotating units: Synchronization refers to the coordination and harmonization of chain load turning units, to work together in a unified and orderly manner. Great for chassis assembly, steel structure welding, extra-long workpiece rotation.

We understand that every plant has unique needs. That's why our foundry mold chain load turner system can be customized with additional accessories and features to suit your specific requirements. From different lifting capacities to specific features, we have the flexibility to create a solution that works best for your business.

RGV Heavy Duty Wheel Sets for Sale