Load turning units for crane can quickly and smoothly complete the rotation and flipping of materials, and are widely used in precision assembly, manufacturing, maintenance and other fields.

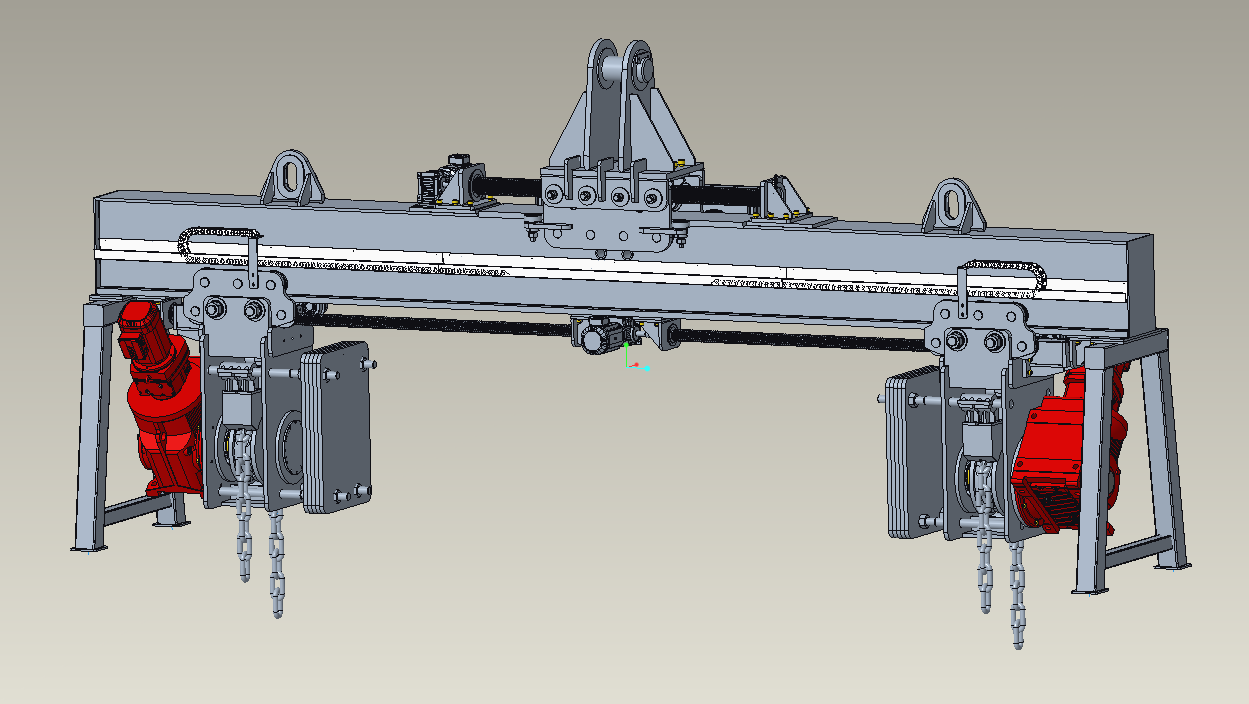

Load turning units for crane can quickly and smoothly rotate and flip materials through precise mechanical structure and electronic control system, and are widely used in precision assembly, manufacturing, maintenance and other fields. It is used in conjunction with the crane hook or trolley to achieve material flipping without changing the original position of the load, which improves the flexibility and efficiency of the operation. Our load turning units are compact, easy to install and maintain, and can be customized according to the specific needs of customers to meet the material handling needs under different working conditions.

How load turning units flip workpieces

The workpiece is firmly fixed to the crane's sling through a hook or a special clamp. Then, the turning device drives the rotating shaft or turntable through an electric motor or hydraulic system to drive the workpiece to rotate. According to needs, the turning device can achieve 90-degree, 180-degree or even 360-degree flipping of the workpiece, and smoothly flip the workpiece from one position to another. During the flipping process, the operator accurately adjusts the flipping angle and speed through the control system to ensure smooth rotation and precise positioning of the workpiece. After the flipping is completed, the workpiece is safely placed in the predetermined position. The whole process is efficient, accurate and safe.

Design features of load turning units

● Equipped with a sophisticated electronic control system, it can achieve precise control during the turning process of the workpiece, including turning angle, speed and position adjustment.

● Equipped with overload protection, limit switch and locking mechanism to prevent equipment damage or workpiece falling due to overload or operating error during the turning process.

● The use of high-strength materials and precision processing technology ensures that the device can withstand the turning needs of heavy and complex workpieces.

● The modular design is easy to customize according to customer needs to meet the turning needs of different sizes, weights and special working conditions.

● The equipment is made of corrosion-resistant materials and adapts to various working environments (such as high humidity, high temperature, corrosive environment, etc.) to ensure long-term stable operation.

In the semiconductor, electronics, aerospace, automobile manufacturing, mechanical processing and other industries, load turning device is widely used to adjust the direction or posture of the workpiece, such as turning heavy parts from a vertical position to a horizontal position, or changing the direction of the workpiece during the production process for easy processing. It is also commonly used in the handling and assembly of precision equipment, such as turning large-sized or irregularly shaped workpieces to ensure their safety and accuracy during handling. Contact us for free design solutions and preferential quotes!

Load Turning Devices