We offer turning devices that can handle extra-long objects, with load capacities ranging from 500 to 80,000 kg. Ideally suited for rotating or turning loads, such as precast concrete elements, casting moulds, steel structures

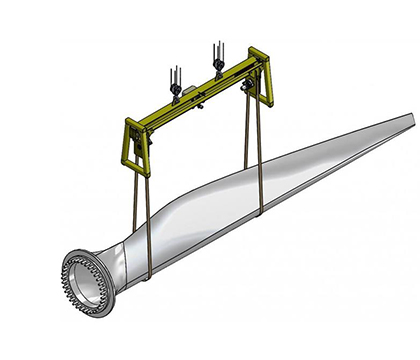

Load turning device, also can be called load spreader beam, load turning beam. Designed in triangular configuration on the top, our load turning device provides much more stability than crane beam. It also help to control the load and when rigged properly, can reduce the chances of:

• Load tipping, sliding or bending

• Crushing or damage to the load because you can control the balance electrically

We offer turning devices that can handle extra-long objects, with load capacities ranging from 500 to 80,000 kg. Ideally suited for rotating or turning loads, such as precast concrete elements, casting moulds, steel structures, stored goods, steel structural, and trailer frames. Different lifting straps, chains, rotation beams, and units are available to suit your specific application needs.

Design Features of Load Turning Device

Belt Sling

When employing a load turning device, choosing a polyester fabric belt is recommended for routine applications. These belts offer elasticity, flexibility, and lightness, making them ideal for delicate surfaces. Nevertheless, it's crucial to note that when handling sharp-edged components, edge and belt protectors are essential. Additionally, if irregularly shaped objects require rotation, a polyester belt remains a suitable option.

Synchronization device

Synchronization involves ensuring that load turning units operate together seamlessly and orderly, making it ideal for rotating long workpieces.

Edge and belt protectors

Edge and belt protectors are specialized accessories intended to protect the edges and belts of lifting slings, preventing damage and extending their lifespan. They are used specifically for safeguarding components and are usually made from aluminum, featuring a hinge and a strong permanent magnet.

Customizable Solutions

Except the load turning beam, modular load turning units are a good choice for irregular part. Load turning units have two separate single-strap modules that attach to separate cranes to lift and rotate long loads. Both modules are motorized and operate in tandem from a single radio remote handheld pendant. For loads with non-uniform circumference along the length, one module can be motorized and the other is an idler.

We recognize that each workshop has distinct requirements. Therefore, our car frame load turning device can be personalized with extra accessories and features, customized to meet your specific needs. Whether you need varying lifting capacities or specialized attachments, we offer the flexibility to tailor a solution that aligns perfectly with your business.