In trailer manufacturing, handling large and heavy components efficiently and safely is crucial. Load turning devices, such as belt load turning devicesand chain load turning devices, play a vital role in this process. These devices enhance productivity and safety by allowing precise manipulation of heavy loads.

1. Chassis Rotating

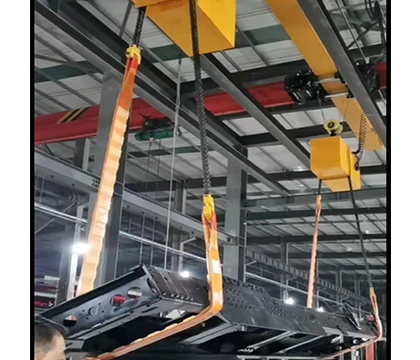

One of the primary applications of load turning devices in trailer manufacturing is the rotation of chassis. The chassis forms the backbone of any trailer, and its construction involves numerous welding, assembly, and inspection processes. Load turning devices allow manufacturers to rotate the chassis easily, providing access to all sides and angles for welding and assembly tasks. This capability not only improves the efficiency of these processes but also enhances the quality of the final product by ensuring thorough inspections and precise welds.

2. Assembly of Flatbed Trailers

Flatbed trailers require precise assembly to ensure they can handle heavy loads safely. During the assembly process, various components, including the frame, axles, and decking, need to be positioned accurately. Belt load turning devices and load turning units enable manufacturers to rotate and position these components effortlessly, ensuring they are aligned correctly. This reduces the risk of assembly errors and enhances the structural integrity of the flatbed trailers.

3. Heavy Truck Manufacturing

In heavy truck manufacturing, components such as frames, engine mounts, and suspension systems must be handled with care. Load turning devices are used to rotate these heavy and often awkwardly shaped components, allowing workers to install parts and perform inspections more efficiently. The ability to rotate the load reduces the need for manual lifting and repositioning, minimizing the risk of workplace injuries and improving overall productivity.

4. Inspection and Quality Control

Quality control is a crucial aspect of trailer manufacturing. Load turning devices play a vital role in the inspection process by allowing inspectors to rotate and examine components from all angles. This comprehensive inspection capability ensures that any defects or issues are identified and addressed promptly, maintaining high quality standards and reducing the likelihood of costly recalls or repairs.

Benefits of Belt Load Turning Devices

• Enhanced Safety: Reduces manual lifting and repositioning, minimizing injury risks.

• Increased Efficiency: Streamlines assembly and inspection processes, boosting productivity.

• Improved Quality: Ensures thorough inspections and precise assembly, reducing errors.

• Versatility: Suitable for various trailer types and components.

In summary, belt load turning devices are indispensable in trailer manufacturing, enhancing safety, efficiency, and quality across various production stages.

Not sure if a rotating lifting device is right for you? Contact us at KFCS and one of our highly qualified safety experts will be happy to discuss your needs. You can count on us to give you honest, expert advice that's aimed at keeping your employees safe and your production on schedule.