We are committed to providing safe and efficient material handling services to various industries, such as pharmaceutical, food, semiconductor, aerospace, automotive, foundry, etc.

We can provide free custom design solutions.

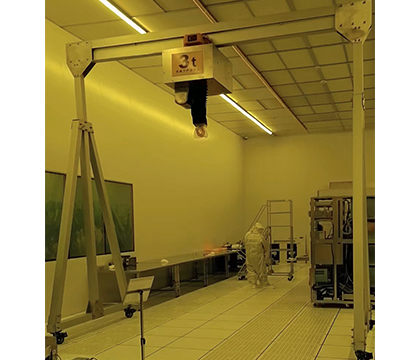

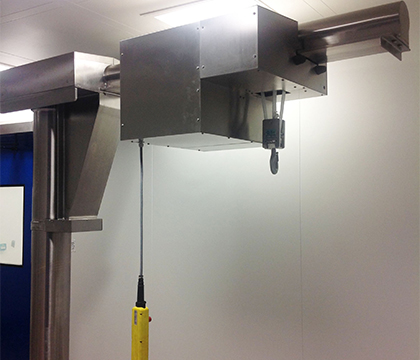

Clean room cranes are lifting equipment specially used in high cleanliness spaces, including cleanroom single girder and double girder cranes, cleanroom jib cranes, cleanroom hoists and cleanroom gantry cranes.

Our load turning device offer safe and stable turning solution, maximum rotation angle of 360 degrees, suitable for turning light to heavy loads.

We offer a variety of floor mounted jib cranes in different specifications to meet the precise and efficient material handling needs of workshops, workstations, and warehouses. Browse our product details to obtain customized services.

Crane hoist solutions include cleanroom hoists, belt hoists, chain hoists and wire rope hoists, supporting different loads and working environments, adapting to various lifting systems, and providing customized services and technical support.

Our portable gantry cranes are made of various materials such as aluminum alloy and steel, providing flexible lifting solutions with adjustable height, mobility and quick assembly and disassembly.

The high performance DRSA wheel block system is suitable for various types of cranes, trolley running mechanisms and industrial rail equipment, and supports multiple installation methods and non-standard customization.

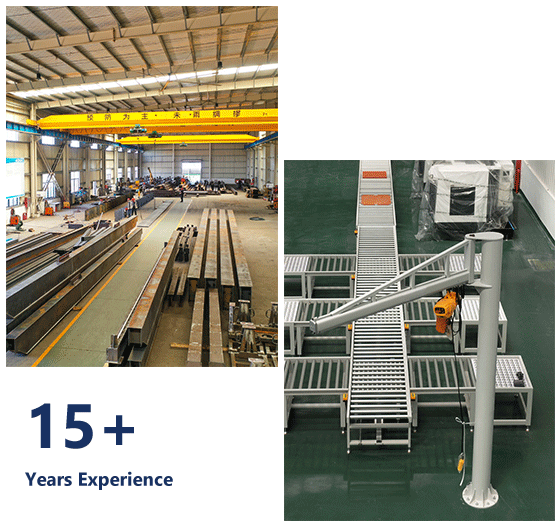

More than 15 years experience in crane industry

Organized productions and quick delivery

Ensures the high standard and cost-effective lifting in design and manufacturing

Continuous support and assistance to customers

Electric fiber rope hoist is innovative type of lifting equipment that combines lightweight, high strength and high safety performance, meeting the needs for efficient and safe operation in controlled industrial environments.

Our synchronized load turning device use precision control systems to smoothly turn heavy workpieces 360° for manufacturing, repair, or assembly purposes.

Driving wheel block system is a power transmission device used in mechanical equipment or industrial transportation systems, providing reliable support and drive solutions for various industrial applications.

Cleanroom belt hoists are protected by 304/316 stainless steel shield, which is highly resistant to wear and tear, and prevent hoists from fading and scratching. Most ss clean room hoists are applied in food and pharmaceutical industries.

The lightweight aluminum portable gantry crane is suspended from the top rail system to provide precise material handling and lifting operations, allowing materials to be moved and positioned within the space.

In the production process of a foundry, casting moulds need to be weighted. These moulds with a height of up to 5m stand in a pit for the casting operation.Covers are placed on the moulds for closing

Cleanroom gantry crane is a specialized type of crane designed for use in cleanroom environments where stringent contamination control is required.

Cleanroom jib crane is a new generation of light hoisting equipment made to adapt to modern production. It is equipped with a highly reliable electric chain hoist

Cleanroom cranes are engineered specifically to meet the stringent requirements of nanotechnology laboratories. These nano cleanroom cranes prevent contamination, ensuring that the cleanroom environment remains pristine.

Clean room cranes offer lifting solution in modular cleanrooms in clean levels from Class 100 to Class 100,000. Clean room cranes are designed to operate within these stringent environments without introducing contaminants.

Cleanrooms are most common for beverage bottle filling operations but also for some food products. Since the bottles are often filled and sealed at elevated temperatures in moist steam filled environm

A cleanroom monorail crane is a specialized lifting solution designed for environments requiring stringent contamination control. It is particularly beneficial in industries like lithium production

Load turning device is essential for every flatbed trailer manufacturing facility since they make the process faster and safer. Every area of your trailer manufacturing facility can benefit from the use of a heavy load turning machine.

For many casting plants, the big challenge is how to rotate the large flask and pour the castings. KFCS offers the best solution for bulky flask rotation - 50 ton Load Turning Device.

Load turning beam, also called load turner, is an equipment for heavy and bulky loads turning. In order to operate in good conditions duringquality control, machining, assembling, finishing, handling,

The deli workshop, known for its stringent hygiene standards, relies heavily on cleanroom lifting cranes to maintain safety and efficiency.

More than 60,000 square meters plant ensures a sufficient place for manufacturing and test. Short lead time with high quality crane is our strength.